Purpose Built Stand

Properties

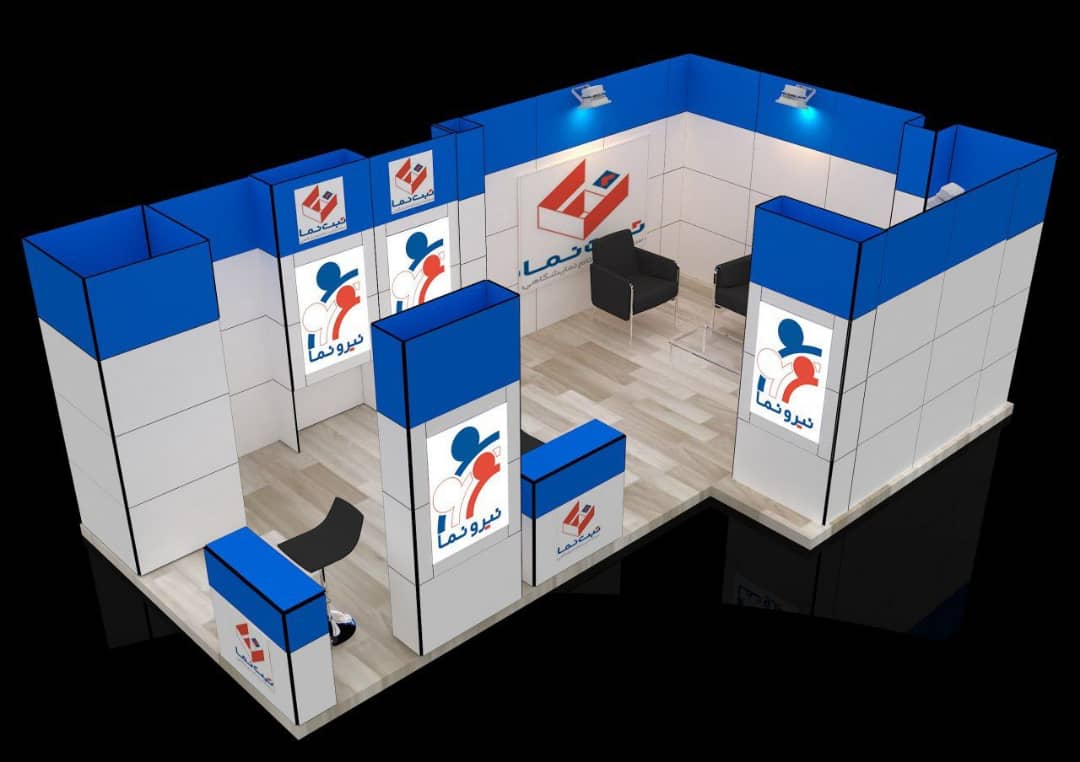

The first thing that you may imagine after hearing word stand is Purpose Built Stand. Actually, there is almost no limitation in materials and dimensions on these kinds of stands. The common ones of Purpose Built Stand made by chipboard, MDF sheet, parquet, electrical devices and lights and various ranges of materials for decoration. In some cases, producers hire steel structures to produce a multiple story exhibit.

Construction processes

Purpose Built Stand could be built in different ways and with various materials. In the following, an ordinary processes will be explained.

1- Design

First step of any production is to provide a plan to cover all the demands of customers and attendees. After that, designers try to show their skills and talents in blueprints. Some pictures such as side, top and perspective view generated by software like Revit and 3D Max will show a clear scheme. So customers can give their points and change color, remove or resize the spaces, elements, etc.

2- Flooring

When the location of stand was specified in fair ground, stand builders cover the ground with square panels. Sometimes especially in open areas, ground has steep slope so they should use steel structural floor. Flooring makes a stunning view of the booth because of creating level in comparison with aisle.

Some companies remove the flooring and just use the simple carpet to decrease the total cost of stand producing.

3- Carpeting

Purpose Built stand commonly is carpeted with parquet. Patterns of parquet are entirely geometrical and angular, squares, triangles and lozenges. Customers, based on their interests, could place their order among various patterns and colors. After carpeting, the edges of parquets are fixed by metal sheets and screws.

4- Shipping and assembling booth elements

Because of the time limitation in producing the booth at fair ground and also to prevent the dust and garbage from being released in production process. Almost all of exhibition managers forbid carpenters to work and just assembling elements like tables, case shows and walls could be done. Therefore these stuffs would be fabricated in the workshop and transported to fair ground.

5- Painting

Without the doubt the color of booth plays a main role in aesthetic aspect. Wise selection of the color and synthesis will provide a natural sense in contrast of modular stands. Surfaces preparation that involves making the surface fit for paint application, for example, making them smooth by applying Plaster of Paris or Stucco/Putty. Painters usually use Acrylic paints. Drying fast, Being repairable, having less odor and more harmony with wooden surfaces highlight this kind of paint.

6- Lighting

Lighting makes the booth seem live, so producers hire the numerous lights, spot lights, halogens, projectors and lamps to achieve this purpose. In some exhibition stand producers are forced to use only energy-saving lights, also because of fire consideration standard cables and wires are permitted to use.

7- Decorating and upholstering

In this step the final works such as installing the glass, tableaus, plants, TVs and furniture are done.

Advantages

- Flexibility in design, performance and material

- Natural and stunning view

- Creating job for skilled workers

- No limitation in dimension and height

- Enable to construct a multiple story

Disadvantages

- Expensive

- Low-speed run

- Need skilled workers

- Make a rubbish

- Complex steps of collection after the show

- Non-reuse materials

Estimated Cost; Depends on design and materials which are used Between 30 to 600 dollars per square meter :

There isent any comments for this subject.